Factory standard packing or according to customer's requirement Port: SZ Lead Time :after payment 1-2 Week CARRIAGE: by air or by ship

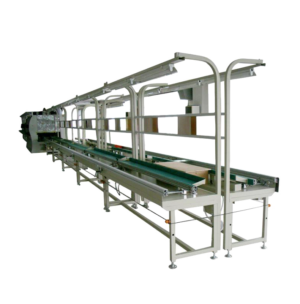

slat chain conveyor

£3,500.00

| Motor | SEW Motor |

| Bend Guide | Green ultra-high molecular polyethylene |

| Supporting Legs | 304 stainless steel stamping pats |

| PLC | Japan Mitsubishi |

| Transducer | France Schneider |

Conveyor & Description 3D ModelShow

Slat Chain Conveyor Systems are used in horizontal conditions and operating at relatively slow speeds. The slat chain conveyor systems are generally used to transport the products which are not conveyable on rollers conveyor systems or belt conveyor systems, due to irregular shape or bottom condition. The slat chain conveyor systems also can be used the assembly line, for example, washing machine assembly line, air conditioner assembly line, tricycle assembly line, motorcycle assembly line…

is one series of our conveyor systems, is also named pallets conveyors. The home appliance assembly line, like TV assembly line, computer assembly line, oven assembly line are usually designed to speed chain conveyor systems. In the speed chain conveyor systems, the semi-finished products on the pallets is driven by free flow chain, goes through every work station to fix all components into a completed products. The special structure of free flow chain make it continuously running but at the same time every work station can be stopped independently by manually controlling the stopper cylinders. This movement of the speed chain conveyor systems is convenient to operate and can make sure one assembling process are finished before next process. We can design the speed chain conveyor systems according to your products and your plant. Welcome to contact us for detail discussion.

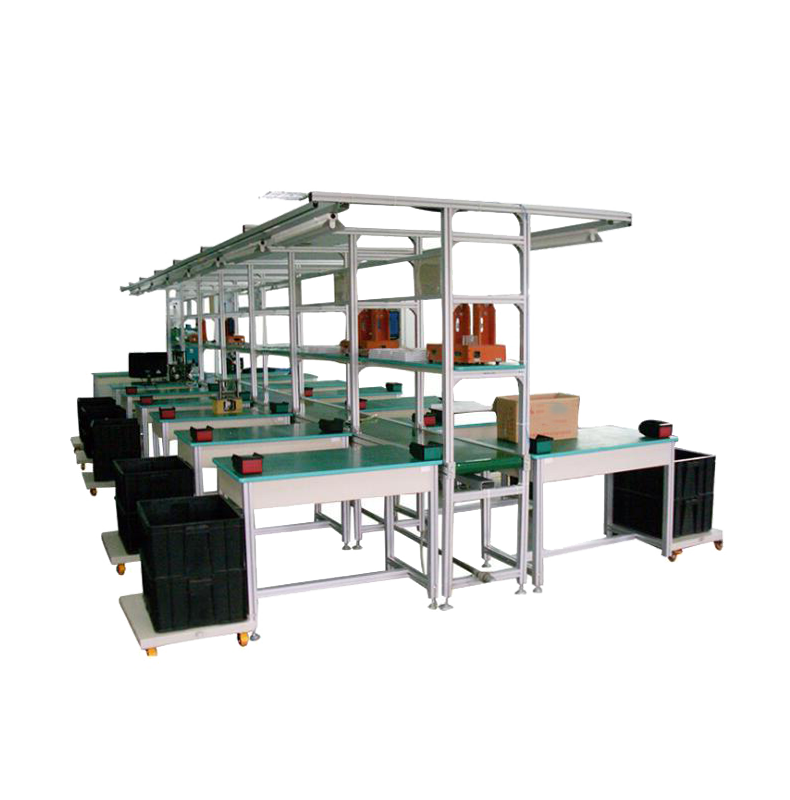

Roller Conveyor Systems are one type of our conveyor systems, also known as gravity roller conveyor systems and powered roller conveyor systems. The material of the roller can be galvanized roller, stainless steel roller, the plastic roller. The roller conveyor systems are wildly used in logistics, warehouse transportation and assembly line. For the roller conveyor systems, the rollers will be installed on the frame, which is the rail of the roller conveyor systems.

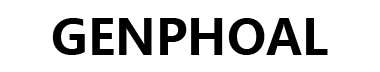

The belt conveyor systems, we have mini belt conveyors, belt conveyors with assembly working table. Our standard conveyor systems include: belt, aluminum frame, aluminum supporting beam, motor, inverter, air pipe, sockets systems, storage shelf, lighting. Belt conveyor systems are widely used in the transporting and small products’ assembly. Because of the short lead time, good quality and competitive prices, more and more companies purchase the belt conveyor systems from our company.

Packaging & Delivery

Our Advantage

- 1. We are factory, accept the OEM/ODM order, We provide free customized designs according to your requirement.

2. We have more than 43 molds, many private molds, we pledged to offer high quality product with competitive price.

3. We have strong professional design and practiced technician team.

4: Delivery time : OEM/ODM normally 1—7 days, MOQ: 100pcs.

4: Payment term: T/T(70% deposit and balance should be pay before shipment) , L/C at sight , O/A……..

5: Warranty & Guarantee: 5 year warranty

6: With certificate of CE, ROHS, FCC, SGS……and different test report.

7: 100% inspect , quality control: IQC( incoming quality control)—IPQC(input process quality control)—FQC( final quality control)—QA(quality assessment) Keep 5S management.

8: sample leading time: sample is 1 days, customized sample need 3 days

相关产品

Conveyor utility belt

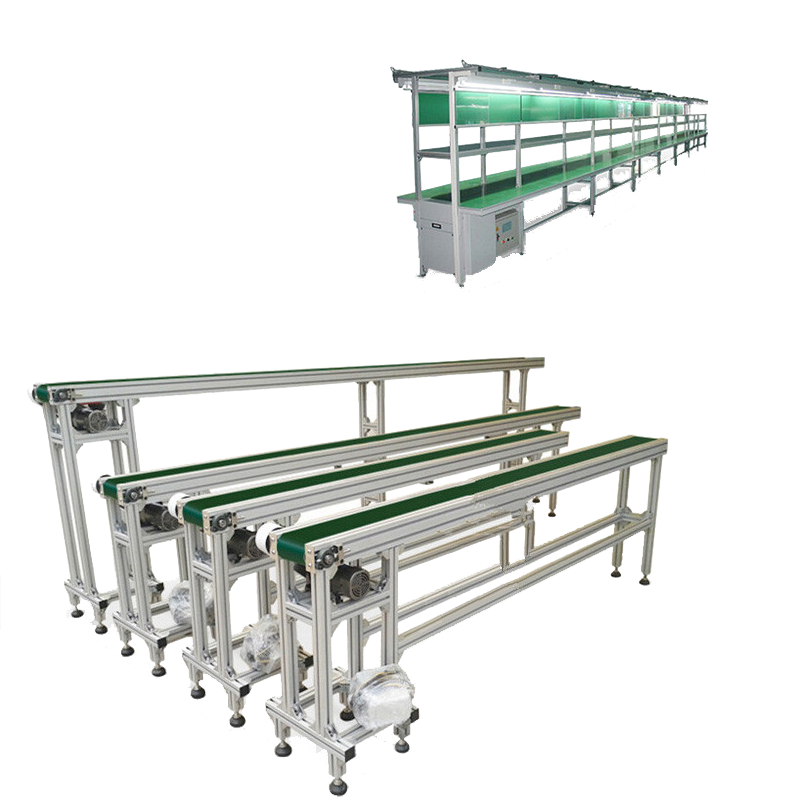

| Workbench definition |

| The workbench is made of high-quality cold-rolled plate. The sturdy work table frame is firm and stable. The table (table) is divided into light type (can bear 200-300 kg), medium-sized (can bear weight 400-500 kg) and heavy work. The table (table) can bear 1000 kg and special worktable; a variety of work table options can be used to meet different requirements; tool cabinets (boxes), side cabinets (boxes), laminates, drawers, drawers can be needed Arbitrarily separated; saves space and has strong applicability. |

| Use range |

| The workbench is suitable for various applications such as mold, fitter, inspection, maintenance, assembly, etc. It has good corrosion resistance, dirt resistance, impact resistance and load bearing capacity. The desktop is specially treated, with anti-corrosion and anti-impact strength. A variety of desktop options can be used to meet different usage requirements. The drawers and cabinet doors are convenient for users to store tools; the power supply hole is reserved on the corner of the table. Install a power outlet. |

| Workbench type |

| According to the different table tops: green composite workbench, anti-static workbench, stainless steel workbench, beech workbench, polymer workbench; According to the different weight bearing: light workbench, medium workbench, load-bearing workbench; According to the different functions, it is divided into: bar workbench, multi-function workbench, workbench, workbench with hanging cabinet, and so on. |

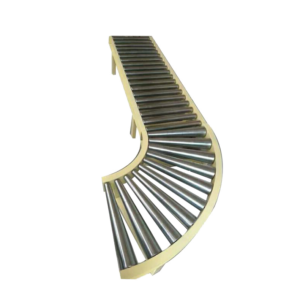

Curve Conveyor

| Roller diameter(D) | According to customer’s requires |

| Roller length(B) | 100mm----1000mm |

| Conveyor height(H) | 1000mm---3000mm |

| Frame size | 90X30X3 /120X30X3 |

| Roller material | Carbon steel/ stainless steel |

| Roller installation method | Female thread |

| Spaces between rollers | According to customer’s requires |

| Color | Blue/grey/green |

| Supporting legs | Adjustable |

| On one hand, standardization reduces flexibility and the freedom of choice. | |

Assembly line working tables

| Specification | |

| Item Type | Belt Conveyor |

| Conveyor Belt Type | PE,PU,PVC,PP,RUBBER |

| Conveyor Belt Width | 20~600mm,Customized |

| Belt Conveyor Height | 200~800mm,Customized |

| Material of Frame | Aluminum Profile,Carbon Steel,Stainless Steel |

| Variable Speed | 0~30meter/min,Customized |

| Voltage | 220V/380V |

| Application | Food,Electrical… |

| Drive Form | Motor Driven Transport |

| Remark | Customized dimensions all can be accepted by our factory

(Furrow,Adjustable,Normal) |

slat chain conveyor belt

Roller Conveyor System

|

Roller Width |

400,500,600,700,800,1000,1200mm Or Customized

|

||

|

Frame |

Carbon Steel, Stainless Steel, Aluminum |

||

|

Roller Material |

Galvanized, Stainless Steel,Plastic |

||

|

Drum Spacing |

100mm, 120mm, 150mm Or Customized |

||

|

Motor |

Tanwan Branded |

||

|

Belt Load-bearing |

10kg /20kg / 30kg Per Meter Or Customerized |

||

|

Conveyor Speed |

Customized,For Exsample: 6meters/min |

||

conveyor roller making machine

standard conveyor systems

|

Material |

stainless steel/custom |

|

Color |

blackl white,custom |

|

Standard |

DIN GB ISO JIS BA ANSI |

|

Grade |

SUS201, SUS304, SUS316, A2-70, A2-80, A4-80, 4.8 6.8 8.8 10.9 12.9 |

|

Brande |

daheng machinery |

|

Thread |

customsized |

|

Used |

Material transfer |