Factory standard packing or according to customer's requirement Port: SZ Lead Time :after payment 1-2 Week CARRIAGE: by air or by ship

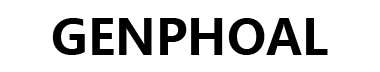

Chain Conveyor System

£3,000.00

| Product Name | Cheap Price cost saving bottle chain conveyor belt systems |

| Chain Material | POM / Stainless steel/Zinc-plated |

| Frame structure | Carbon Steel,Stainless steel,Aluminum |

| Width | 400mm, 500mm, 600mm, 18”, 24” |

| Work temperature | -20°C~+60°C |

| Speed | 10-80 m/min |

| Working load(25°c) | 200N-2000N |

| Key Word | chain conveyor belt |

| Main application:

Conveying small ball bearings, batteries, bottles (plastic and glass), cups, deodorants, electronic components and electronic equipment. |

|

Installation and adjustment

After the equipments are arrived at the customer’s site, the customers is responsible for unpacking and arranging the equipment according to the placement drawing; and do under our install-adjust technicians’ guidance.

According to requirement of water, electricity, air and steam consumption and the demands of quality level and pipeline, the User should connect the wire, cable and pipe of water, air and steam to the special position ordered in the installation area of production line ahead of time. Other relevant matching equipment and project should be

finished before we adjust our equipment.

We’ll bring a suit of portable installation and adjustment tools ourselves during the period of installing and adjusting, the other instruments we need should be furnished by the customer for free including oxygen, acetylene angry, argon, etc. needed in the installation and adjustment site.

The customer should dispatch the capable person to accept training in the installing site.

Training

We are responsible for offering the technical training to user. The training content includes the structure and maintenance of the equipments, control and operation of the equipments. The training lessons are finished in the process of installation and adjustment. Through training, users’ technical staff can grasp and the skill of operation and maintenance proficiently, and deal with the general troubles in time.

Quality assurance

We guarantee the goods offered are brand-new, unused, with latest design and suitable material made, and we guarantee the specification of the equipments is consonance with the contract.

We are responsible for the fault and damage of the production line caused by our design, technology, manufacture, installation, adjustment and material defect etc that all belong to our responsibility.

Maintenance

Offer 12 months maintenance period to the problem that caused by our design, manufacture and the material quality, and offer the relevant parts and effective service for free for above reason. We will offer a widely and favorable technical support, after service all the time after guarantee period.

Material:

Conveyor frame: Stainless Steel, Aluminum

Conveyor belt: PP flexible chain

Speed: adjustable 1-30m/min

It is mainly used for bottle, glass, box, bag, battery transmission

All our conveyor lines are designed as customers actual requirement.

The following information we need from you before our design project and quotation.

1. Your layout

2. Your information about the transmission items. (like the maximum and minimum weight and size)

3. Your Capacity and requirement speed.

4. Material requirement

5. Detail size for the conveyor line

6. Other required specail function for the conveyor line

7. Your requirement on motor

etc.

You can also choose different color as your wish.

Packaging & Delivery

Our Advantage

- 1. We are factory, accept the OEM/ODM order, We provide free customized designs according to your requirement.

2. We have more than 43 molds, many private molds, we pledged to offer high quality product with competitive price.

3. We have strong professional design and practiced technician team.

4: Delivery time : OEM/ODM normally 1—7 days, MOQ: 100pcs.

4: Payment term: T/T(70% deposit and balance should be pay before shipment) , L/C at sight , O/A……..

5: Warranty & Guarantee: 5 year warranty

6: With certificate of CE, ROHS, FCC, SGS……and different test report.

7: 100% inspect , quality control: IQC( incoming quality control)—IPQC(input process quality control)—FQC( final quality control)—QA(quality assessment) Keep 5S management.

8: sample leading time: sample is 1 days, customized sample need 3 days

相关产品

Conveyor utility belt

| Workbench definition |

| The workbench is made of high-quality cold-rolled plate. The sturdy work table frame is firm and stable. The table (table) is divided into light type (can bear 200-300 kg), medium-sized (can bear weight 400-500 kg) and heavy work. The table (table) can bear 1000 kg and special worktable; a variety of work table options can be used to meet different requirements; tool cabinets (boxes), side cabinets (boxes), laminates, drawers, drawers can be needed Arbitrarily separated; saves space and has strong applicability. |

| Use range |

| The workbench is suitable for various applications such as mold, fitter, inspection, maintenance, assembly, etc. It has good corrosion resistance, dirt resistance, impact resistance and load bearing capacity. The desktop is specially treated, with anti-corrosion and anti-impact strength. A variety of desktop options can be used to meet different usage requirements. The drawers and cabinet doors are convenient for users to store tools; the power supply hole is reserved on the corner of the table. Install a power outlet. |

| Workbench type |

| According to the different table tops: green composite workbench, anti-static workbench, stainless steel workbench, beech workbench, polymer workbench; According to the different weight bearing: light workbench, medium workbench, load-bearing workbench; According to the different functions, it is divided into: bar workbench, multi-function workbench, workbench, workbench with hanging cabinet, and so on. |

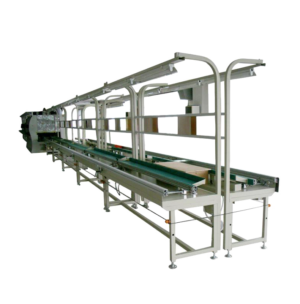

belt conveyor systems

pallet chain conveyor

Flat band driving conveyor

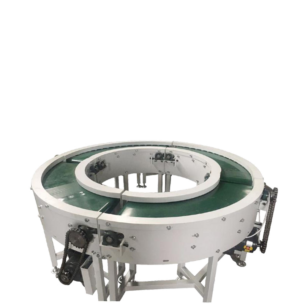

| Specification | |

| Item Type | Belt Conveyor |

| Conveyor Belt Type | PE,PU,PVC,PP,RUBBER |

| Conveyor Belt Width | 20~600mm,Customized |

| Belt Conveyor Height | 200~800mm,Customized |

| Material of Frame | Aluminum Profile,Carbon Steel,Stainless Steel |

| Variable Speed | 0~30meter/min,Customized |

| Voltage | 220V/380V |

| Application | Food,Electrical… |

| Drive Form | Motor Driven Transport |

| Remark | Customized dimensions all can be accepted by our factory

(Furrow,Adjustable,Normal) |

slat chain conveyor

| Motor | SEW Motor |

| Bend Guide | Green ultra-high molecular polyethylene |

| Supporting Legs | 304 stainless steel stamping pats |

| PLC | Japan Mitsubishi |

| Transducer | France Schneider |

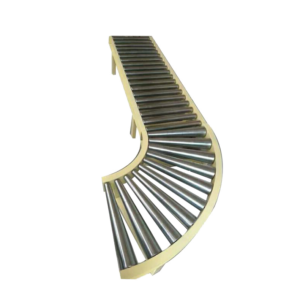

Roller Conveyor System

|

Roller Width |

400,500,600,700,800,1000,1200mm Or Customized

|

||

|

Frame |

Carbon Steel, Stainless Steel, Aluminum |

||

|

Roller Material |

Galvanized, Stainless Steel,Plastic |

||

|

Drum Spacing |

100mm, 120mm, 150mm Or Customized |

||

|

Motor |

Tanwan Branded |

||

|

Belt Load-bearing |

10kg /20kg / 30kg Per Meter Or Customerized |

||

|

Conveyor Speed |

Customized,For Exsample: 6meters/min |

||

conveyor roller making machine

2019 PU band conveyor

-

Specification Item Type Belt Conveyor Conveyor Belt Type PE,PU,PVC,PP,RUBBER Conveyor Belt Width 20~600mm,Customized Belt Conveyor Height 200~800mm,Customized Material of Frame Aluminum Profile,Carbon Steel,Stainless Steel Variable Speed 0~30meter/min,Customized Voltage 220V/380V Application Food,Electrical… Drive Form Motor Driven Transport Remark Customized dimensions all can be accepted by our factory (Furrow,Adjustable,Normal)