Factory standard packing or according to customer's requirement Port: SZ Lead Time :after payment 1-2 Week CARRIAGE: by air or by ship

Powder Coating Machine

£5,000.00

|

Painting Line

|

Metals, Steel, Iron, Hardware, Plastic

|

||

|

Painting Style 1

|

Electrostatic Painting,Powder Coating Line, Pipe Coating Line

|

||

|

Painting Style 2

|

Oil Painting, Water-based Painting

|

||

|

Coating 1

|

Powder Coating Line, Powder Coating, Hard Coating, Pipe Coating

|

||

|

Coating 2

|

Zinc Coating,Dip Coating, Coating Industry, Surface Coating

|

||

|

Application 1

|

Video Recorders, PDA, Camera Shell, Audio, Hair Dryer, MD, Toys

|

||

|

Application 2

|

Computer, Telephone, Mobile Phone Shell, DVD/VCD, Game Consoles

|

||

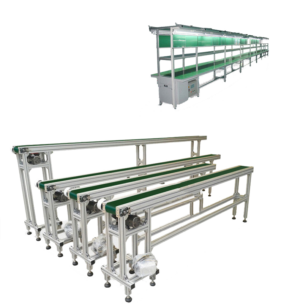

Powder Coating Equipment Automatic electrostatic powder coating painting production line

Different Products require Different Designs. Our engineers analyze the requirements before developing equipment that can be incorporated into the overall automatic powder coating line. aluminum profiles powder coating machine

Processes of the pretreatment:

Degreasing – water rinsing – water rinsing – Derusting – water rinsing – water rinsing – iron phosphating / zinc phosphating – chromium – ……

Stainless steel cabinet and tanks.

PP noozles;

Filters;

SUS304 stainless steel water tanks;

Water pump;Pipe;Other related parts.

SPRAYING PRETREATMENT / DIPPING TANK PRETREATMENT

metal parts powder coating line aluminum profiles powder coating machine

Bridge Structure Oven

Bridge structure oven has advantage in the saving energy because of its structure. Heater will be kept in the upper of the oven, and the air curtain at the both end of the oven helps to prevent the heated air from escaping.

Floor- Mounted Structure Oven

Easier space especially height needed;

Adjustable opening sizes helps to prevent the heaters escaping as most as they can.

Various Heating Systems for options

Diesel, natural gas, LPG, Electric heating, and infrared catalytic heating are available.

Stainless steel heater exchanger and high temperature resistance fan & motor make sure the safe operations and long life of the equipment.

Automatic Coating

Manual Coating

manual coating stations are specially designed. And in this design, workers can check and recoat the profiles which may not be coated very perfectly by the reciprocators with guns.

Automatic coating + Manual Coating

This design can make sure all the work parts be coated perfectly and no missed.

Feature:

Rate of Recovery:≥98%

Suitable for multi color, quick-color change .

Min 30mins could change one color.

Powder suppler center.

Suitable for automatic coating.

Automatic booth floor cleaning system.

PLC and touch screen control system. Support multiple languages.

Multi Cyclone Powder Recovery System

Feature:

Rate Of Recovery: ≥98%.

Suitable for single color coating.

Powder supply center and solid filter system.

Suitable for automatic coating.

Automatic booth floor cleaning system.

PLC and Touch screen control system. support multiple languages.

Movable Bag Type Powder Coating Booth

Rate of Recovery:≥96%

Suitable for multi color, quick-color change .

One color need one movable bag.

Min 40mins could change one color.

Powder suppler center.

Suitable for automatic coating.

Automatic booth floor cleaning system.

PLC and touch screen control system. Support multiple languages.

Packaging & Delivery

Our Advantage

- 1. We are factory, accept the OEM/ODM order, We provide free customized designs according to your requirement.

2. We have more than 43 molds, many private molds, we pledged to offer high quality product with competitive price.

3. We have strong professional design and practiced technician team.

4: Delivery time : OEM/ODM normally 1—7 days, MOQ: 100pcs.

4: Payment term: T/T(70% deposit and balance should be pay before shipment) , L/C at sight , O/A……..

5: Warranty & Guarantee: 5 year warranty

6: With certificate of CE, ROHS, FCC, SGS……and different test report.

7: 100% inspect , quality control: IQC( incoming quality control)—IPQC(input process quality control)—FQC( final quality control)—QA(quality assessment) Keep 5S management.

8: sample leading time: sample is 1 days, customized sample need 3 days

相关产品

Clean Room

| CLASS LEVEL | MODEL NUMBER | INNER SIZE | AIR FLOW VOLUME |

| CLASS 100/ISO5 | G6 *8 | 2000 * 3000 * 2400 | 6600 |

| G 12*18 | 3650 * 5490 * 2400 | 13200 | |

| G12*25 | 3650 * 7620 * 2400 | 17600 | |

| G20*30 | 6100 * 9150 * 2400 | 56000 | |

| CLASS 1000/ISO6 | G6 *8 | 2000 * 3000 * 2400 | 2200 |

| G 12*18 | 3650 * 5490 * 2400 | 6600 | |

| G12*25 | 3650 * 7620 * 2400 | 8800 | |

| G20*30 | 6100 * 9150 * 2400 | 17600 | |

| CLASS 10000/ISO7 | G6 *8 | 2000 * 3000 * 2400 | 1100 |

| G 12*18 | 3650 * 5490 * 2400 | 2200 | |

| G12*25 | 3650 * 7620 * 2400 | 5500 | |

| G20*30 | 6100 * 9150 * 2400 | 11000 | |

| CLASS 100000/ISO8 | G15*30 | 4570 * 9150 * 2400 | 4000 |

| G16*33 | 4870 * 11000*2400 | 5200 | |

| G20*40 | 6100 * 12100*2400 | 6600 |